ENGINEERING & construction

In our development, we primarily implement developments according to customer requirements. If required, we can also completely manufacture, assemble and commission the elaborated solutions.

In order to be able to fully cover your requirements, we of course also work with external specialists.

We are well equipped:

• 3 CAD stations with Inventor 2017 (3D) and AUTOCAD 2017

• DXF, STEP import and export enabled

• A0 large format printer HP Designjet T520

Project examples customized machines

Spray Robots

Three different types of spray robots have been developed for the precise discharge of test liquids in the agrochemical industry. The robots are built on various basic machines: pedestal tractor, trailer and on a tracked dumper. On each robot up to 80 test tubes with test products can be inserted. These are mixed up and then precisely discharged on the test area.

Tabbing machine for pizzas

Pizzas exit production and enter the tabbing machine. Cardboard tabs from a hopper are attached to the pizzas, labelled by laser print and glued on.

Details to the Tabbing Machine

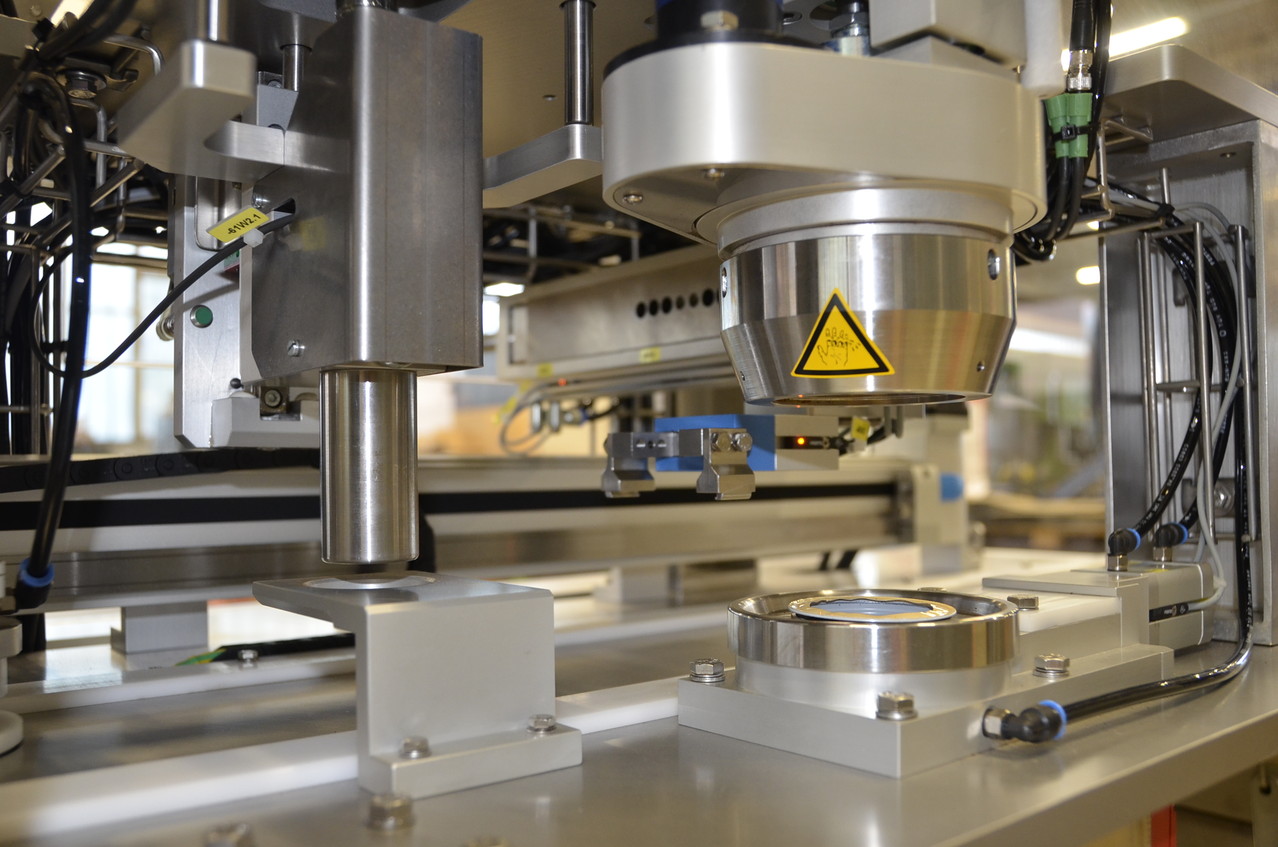

Capsule tester

Coffee capsules are inserted in the tester manually. Following the start-up of the machine, various methods are employed to run a fully automatic capsule quality test.

Details to the Capsule Tester

Examples Packaging Machines

We are specialists for complex cartons in best quality! Our experience allows us to find a solution for each packaging which can also be used industrially.

Horizontal cartoner

This type of machine is used to erect a pre-glued carton (case) in such a way that a tube is formed. In a further step, the product, a bag or a carton base is pushed horizontally into the formed tube. The packaging is sealed in the final step.

Carton erector

In the carton erector, a folding tool with a forming head is used to punch, glue or hook a carton from the hopper to form the packaging base or lid. In general, the base then is filled with

products automatically and the packaging is sealed by a lid.

Kontakt

TecSup GmbH

Obere Zollgasse 71

CH-3072 Ostermundigen

| Tel.: | +41 31 931 00 54 * |

| Mail: | info@mfbern.ch |

Öffnungszeiten

Mo-Do 7:30-12:00 / 13:30-17:00

Fr 7:30-12:00 / 13:30-16:30

deutsch | english | Share on Facebook

© 2021 TecSup GmbH