Horizontal cartoner

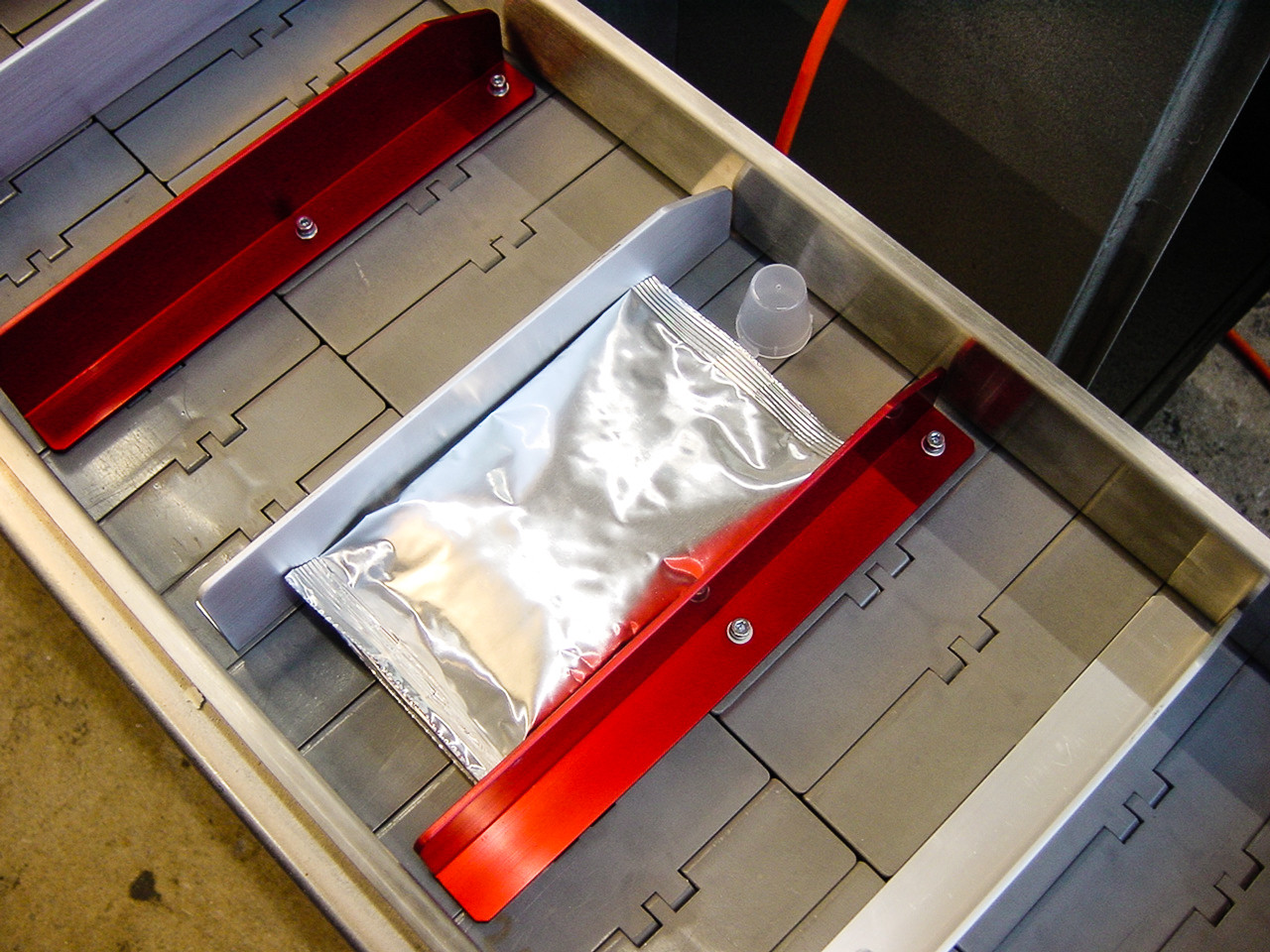

This base machine called ZetVITE is used to erect a pre-glued carton (case) in such a way that a tube is formed. In a further step, the product, a bag or a carton base is pushed horizontally into the formed tube. The packaging is sealed in the final step.

The sale of spare parts as well as the service of these machines is now completely guaranteed by TecSup GmbH. This step became necessary after the Zeiler AG company sold the ZetEngineering division to the Migros subsidiary Limmattdruck AG, which in turn was sold to the RLC Packaging Group. In 2018, ZetEngineering was closed without replacement by the RLC.

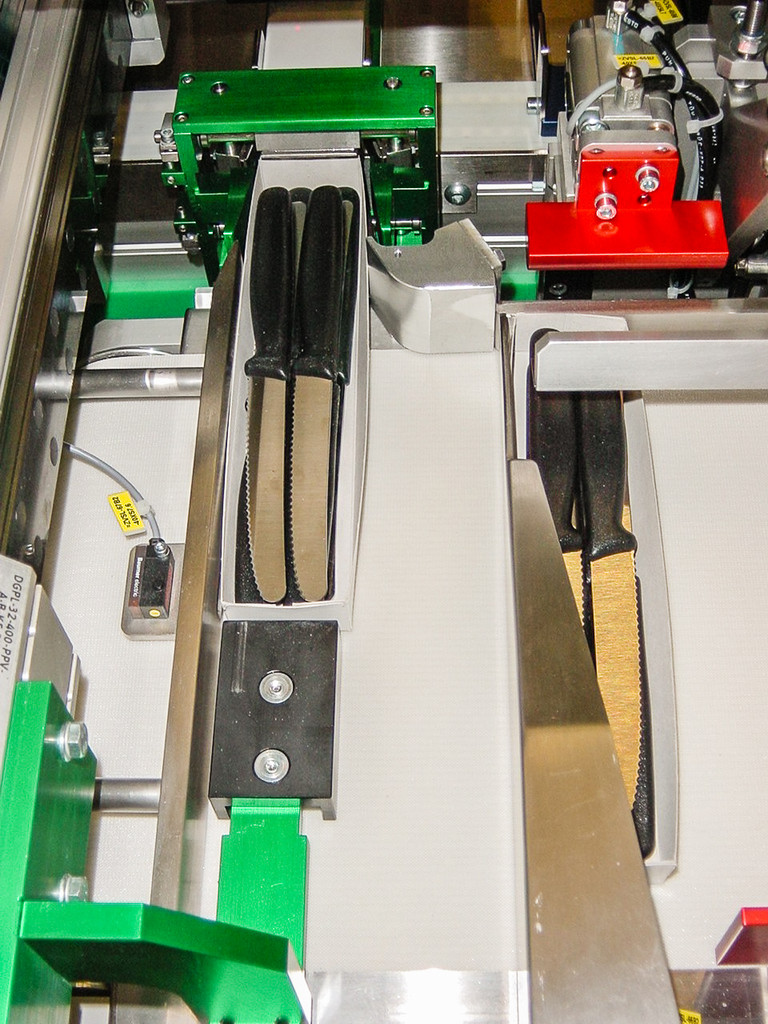

Horizontal cartoner with casepush

Horizontal cartoner with bagpush

Operation

intermittent

Output range

up to 55 cycles/min. acc. to material, packaging format and fill material

Format range

min. 50 x 25 x 100 mm

max. 170 x 80 x 240 mm

Required personnel

1 part-time staff to load the hopper and the hot-melt aggregate as well as to monitor the system

Format change

threaded spindle and replacement parts

Changeover period

ca. 30 minutes

Standard equipment

- minimum level control in in folding box hopper with visual display

- oil-free vacuum pump

- hot-melt outline application

- electronic hot-melt temperature control timer

- PLC control

- apron conveyor chain or toothed belt for product feed

- Product infeed

Additional equipment

- hot-melt aggregate (Robatech or Nordson)

- blind embosser

- hot embosser

- labeller

- central lubrication

- swing-arm inserter

- product grouping and single cycle unit

- also available as manual infeed model

Kontakt

TecSup GmbH

Obere Zollgasse 71

CH-3072 Ostermundigen

| Tel.: | +41 31 931 00 54 * |

| Mail: | info@mfbern.ch |

Öffnungszeiten

Mo-Do 7:30-12:00 / 13:30-17:00

Fr 7:30-12:00 / 13:30-16:30

deutsch | english | Share on Facebook

© 2021 TecSup GmbH